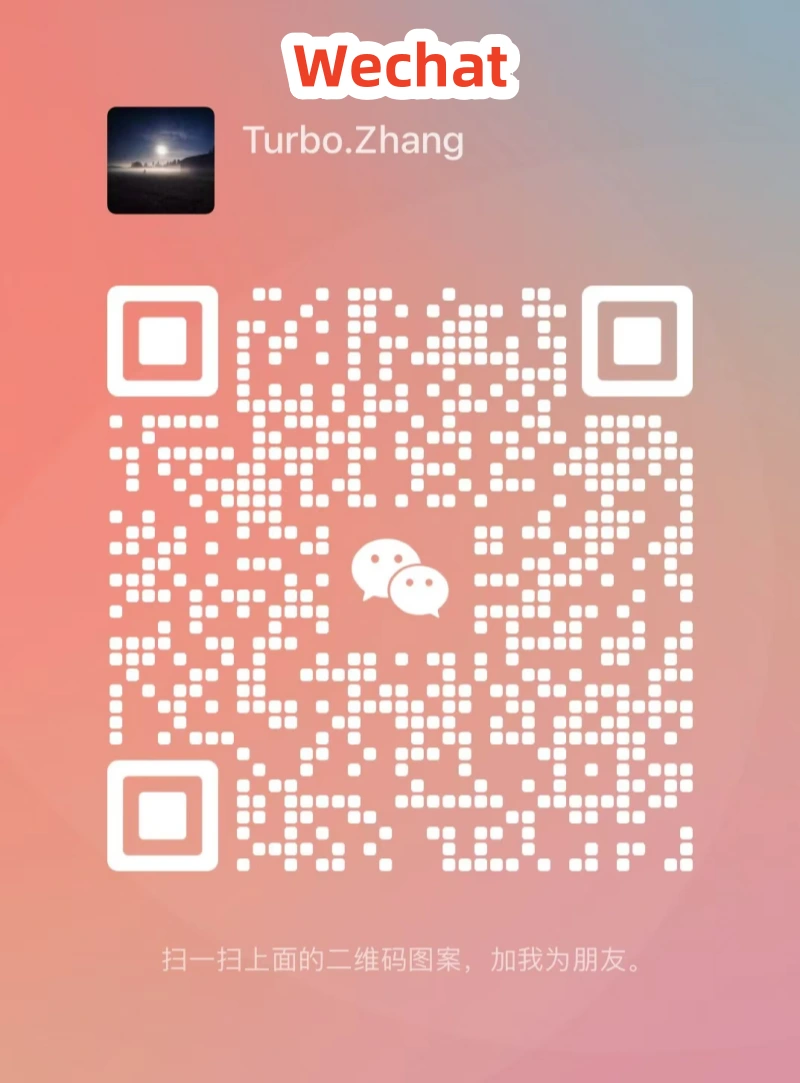

Scan the WeChat code to contact us

Mainly engaged in various brands of turbochargers.

The German automotive industry is undergoing a profound transformation. Following adjustments by several giants, the century-old commercial vehicle brand has taken a difficult step. Volkswagen Group’s subsidiary, MAN Truck & Bus, recently announced plans to reduce its German workforce by approximately 2,300 employees over the next decade through natural attrition.

This workforce reduction plan will not involve forced layoffs but will be implemented gradually through voluntary means such as employee retirements. The positions affected will be concentrated across three main plants: the Munich headquarters plant will be the most impacted, losing about 1,300 positions; the Salzgitter plant is expected to see a reduction of about 600 positions; and the Nuremberg plant will cut around 400 positions. MAN currently employs about 15,000 people in Germany. After this adjustment, the workforce size is expected to be maintained at approximately 13,000.

A company spokesperson explained that this decision is a response to multiple pressures. First, there is a persistent weakness in demand for trucks in the German domestic market, which the company must adapt to. Second, high energy and labor costs are severely squeezing the company’s profit margins. Additionally, increasingly fierce competition from Asian manufacturers is posing significant pressure.

MAN stated that the company is entering a phase requiring intensive investment. This move aims to generate sustained profits to fund the expansion of its future product portfolio. At the same time, the company emphasized that core production sites such as Munich and Nuremberg will be retained.

However, Germany’s powerful IG Metall union has expressed serious concerns about the plan. Union representatives pointed out that MAN’s plans to transfer some production to parent company Volkswagen’s plant in Poland could, in the long run, threaten the viability of the German facilities. They questioned whether retaining only assembly operations in Germany would be sustainable if core manufacturing processes were fully relocated.

MAN’s job cuts are a microcosm of the German automotive industry’s challenges amid the transition to electrification, rising costs, and intensifying global competition. Balancing domestic employment with industrial upgrading while pursuing efficiency and competitiveness remains a long-term challenge for Germany’s manufacturing sector.