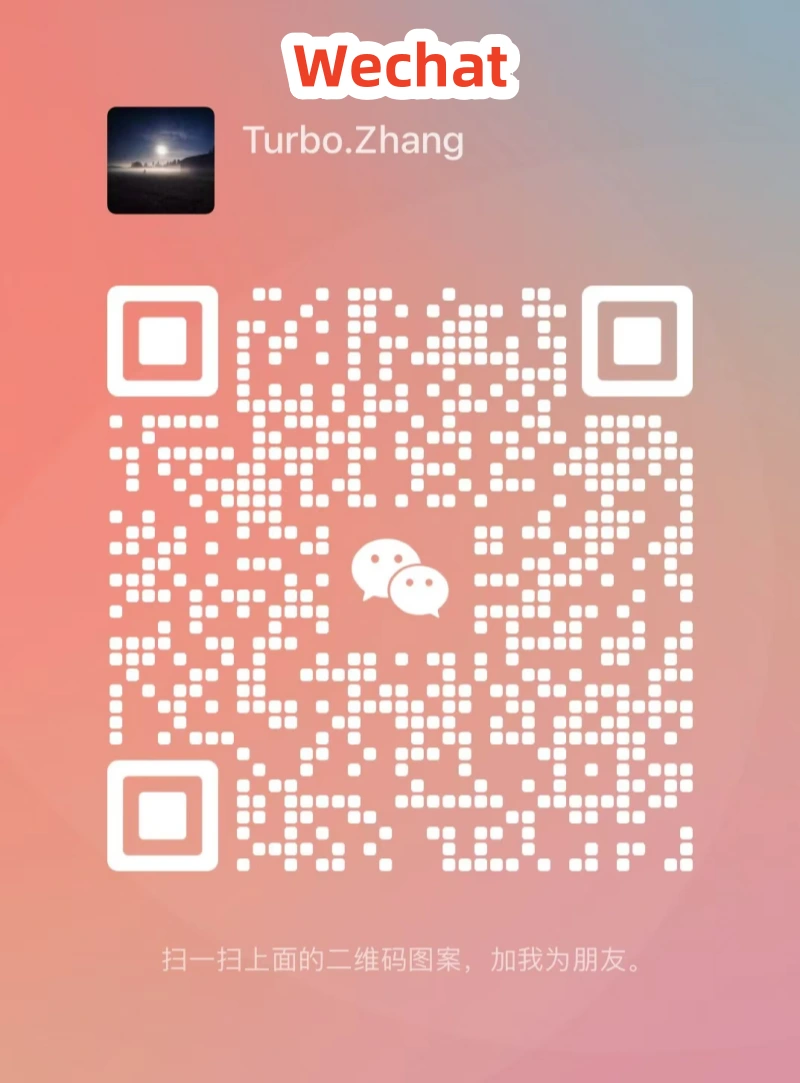

Scan the WeChat code to contact us

Mainly engaged in various brands of turbochargers.

Cummins Turbo Technologies is innovating with two-stage turbochargers for medium-heavy duty engines, building on decades of Holset® turbocharger reliability. These systems use two turbochargers in series to boost engine power and efficiency, crucial for meeting modern emissions standards and fuel economy demands.

How Two-Stage Turbocharging Works:

Unlike single-stage turbos, two-stage systems employ a smaller, high-pressure (HP) turbo and a larger, low-pressure (LP) turbo. Exhaust gas first drives the HP turbine, which powers the HP compressor to pre-compress air from the LP compressor. The remaining exhaust energy then drives the LP turbine and compressor for further air pressurization. Bypass valves optimize performance across engine speeds, directing exhaust flow to either turbo as needed. This balanced approach enhances low-end torque, peak power, and altitude performance.

Types of Two-Stage Systems:

Cummins utilizes various two-stage configurations including:

Advantages:

Two-stage turbochargers offer superior performance by:

Challenges:

Despite benefits, two-stage systems present engineering challenges:

Cummins overcomes these challenges through advanced engineering, rigorous testing, and material expertise, successfully implementing two-stage turbocharging to improve engine performance, efficiency, and emissions compliance across diverse engine platforms.