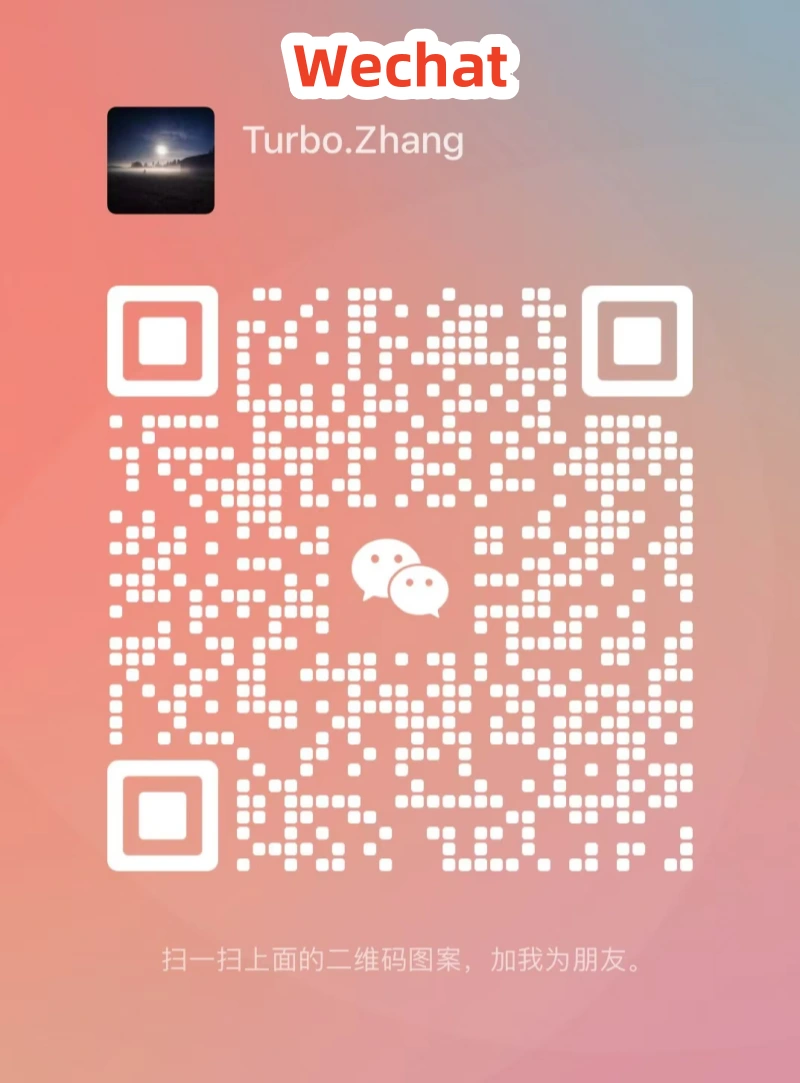

Scan the WeChat code to contact us

Mainly engaged in various brands of turbochargers.

Auburn Hills, Michigan, September 7, 2018 – BorgWarner has developed a new bidirectional flow channel turbocharger for light vehicle gasoline engines with high transient response requirements. This new turbocharger significantly improves engine response time in low-speed vehicle acceleration applications. The unique bidirectional flow channel volute geometry design can completely separate the engine exhaust gas pulses. Compared with traditional dual flow channel turbochargers, the turbine impeller can utilize more exhaust gas energy to generate boost. This new turbocharger further enriches BorgWarner’s engine boosting product line, providing new high-performance solutions for light-duty gasoline-powered vehicles and helping automotive OEMs achieve their product development goals.

Robin Kendrick, president and general manager of BorgWarner Turbocharging Systems, said: “With BorgWarner’s exceptional expertise in developing advanced engine boosting technologies, we are able to take a systematic approach to technology development and help customers choose the right one. Turbocharging solution. Our engineering team recognized that bidirectional flow turbochargers can provide faster engine response for light-duty vehicles with high transient response requirements and we are excited to introduce this new solution. to the market.”

A turbocharger generally consists of a turbine and a compressor. It uses the energy in the high-temperature, high-pressure airflow discharged as exhaust gas from the engine and converts it into compressed or “supercharged” air and sends it to the engine. A bidirectional turbine directs exhaust gases into two separate volutes (cylindrical channels) within the turbine. Each volute transmits the exhaust gas pulse energy directly to half of the turbine wheel.

Traditional twin-channel turbochargers separate the airflow to the turbine wheel by adding a dividing wall in the turbine casing, thereby forming a “side-by-side” channel volute design. However, this design requires that the airflow from both channels enter a smaller common channel just before flowing to the turbine wheel. A common passage results in leakage of airflow and pulse energy from both parts, resulting in a loss of available energy to the turbine wheel.

BorgWarner’s dual-flow turbine is able to capture more exhaust pulse energy than a dual-flow turbine by eliminating a common passage and completely separating the two airflow channels. At low engine speeds, where the time between exhaust pulses is longer and the amount of exhaust flow varies greatly, more energy can be created using the pulse energy from the engine than using the exhaust gases alone. , thereby better driving the turbine impeller. This ability to utilize more energy at low rpm is also key to achieving fast boost response, helping to meet the demand for engine responsiveness in modern turbocharged engines.

Prior to the introduction of BorgWarner’s new solution, bidirectional flow channel turbochargers were only available on a limited basis in diesel engines for commercial vehicles, while BorgWarner has been developing new ones for gasoline engines since 2012. The first-generation bidirectional flow channel turbocharging technology has been successfully applied in a certain automobile brand’s full-size pickup truck production line. This is the first bidirectional flow channel turbocharger for the light vehicle market. By continuously expanding its rich engine supercharging product line, BorgWarner provides advanced supercharging technology to almost all automobile manufacturers in the world. As a leading provider of clean and efficient drive system solutions for internal combustion engines, hybrids and electric vehicles, BorgWarner is also committed to helping automakers meet increasingly stringent global emissions regulations when designing its products.