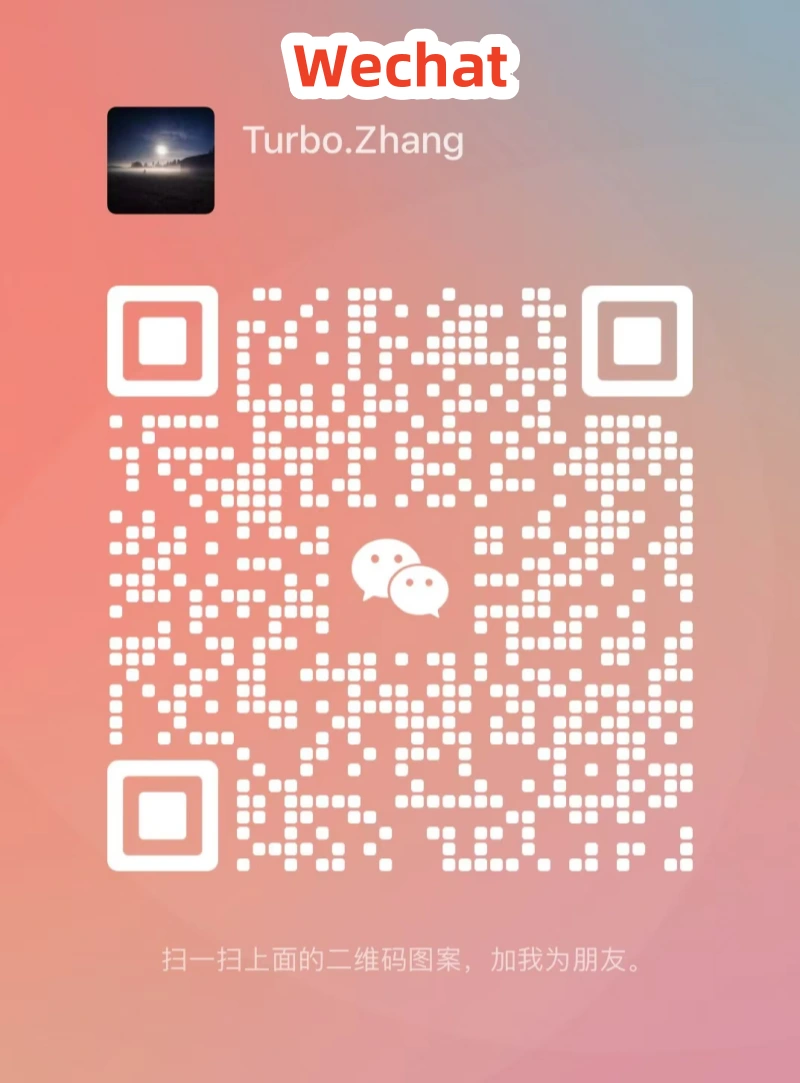

Scan the WeChat code to contact us

Mainly engaged in various brands of turbochargers.

ROHL, Switzerland, October 17, 2019 – Garrett (NYSE: GTX) has confirmed that it is developing the world’s first “E-Turbo” for the mass passenger car market, expected to be launched in 2021.

Garrett’s announcement comes as automakers turn to electrified engine technology to meet the industry’s challenges of increasing energy efficiency and new regulatory emissions targets, while still meeting consumer demand for greater vehicle performance and affordability. Garrett’s first E-Turbo application will be in premium, high-performance vehicles. Garrett is also advancing 10 applications in different segments of the world’s three major automotive markets.

The turbocharger harnesses the energy of exhaust gases that would otherwise leave the exhaust pipe to drive the turbine wheel, which is connected to the compressor wheel via a shaft. The compressor wheel pushes more air into the engine, creating the now familiar “turbocharger” that accelerates the vehicle. This enables automakers to use smaller, more efficient engines, helping improve fuel efficiency and reduce CO2 emissions without sacrificing vehicle performance.

Garrett’s E-Turbo follows this basic principle but adds a small electric motor on the shaft between the two impellers, which facilitates two innovations. First, the electric motor can quickly start the turbocharger to provide boost immediately at idle, effectively eliminating the lag between the driver pressing the accelerator and feeling acceleration. In addition, by providing electricity to the turbocharger, the design constraint of prioritizing turbine efficiency to drive the compressor at low engine speeds is also eliminated. When air flow is low, the additional electricity is used to compensate, which allows Garrett to use a larger turbocharger that more closely matches the engine’s natural optimal operating point.

Second, and most excitingly, given the future hybridization trend in different vehicle segments, the E-Turbo uses a small electric motor to generate electricity and charge the hybrid battery, electrically recovering the energy of the consumed and wasted exhaust gas. This onboard power capability provides automakers with more options for designing hybrid powertrains.

Garrett Gasoline Electric Turbocharger Application Case

Garrett has been working with a global automaker and other industry suppliers to demonstrate the power of this new technology. At a conference in Germany earlier this year, Garrett engineers talked about multiple tests that showed that the E-Turbo outperformed current production small turbochargers at all speeds. Most impressive was that at low engine speeds (1500 rpm), it took only 1 second to reach target torque, while the current production model takes 4.5 seconds.

Overall, the results show that the E-Turbo has the potential to improve basic engine performance and meet future legislative requirements for fuel economy and emissions. In Garrett’s application case, the rated power was increased by 16%, the torque increased by 10.5%, and the time required to accelerate from 60 km/h to 100 km/h was reduced from 11 seconds to 8.8 seconds (a time reduction of -25%).

Next-Generation Software

Garrett’s next-generation software can integrate boost control algorithms in existing engine control modules (ECMs), improving the performance and fuel efficiency potential of electric turbocharger systems. The addition of Garrett’s software will help optimize turbocharging, torque, efficiency and emissions performance. In addition, as vehicle manufacturers focus on all aspects of powertrain system design to meet increasingly stringent environmental standards, the software also uses predictive and intelligent diagnostic functions to monitor the health of the entire air circuit within the vehicle.

Garrett’s software creates a new control subsystem for electric turbochargers, redefining the interaction between traditional engine control modules (ECMs) and mechanical turbochargers. ECM partners provide an integrated environment, including interfaces and memory allocation, which enables Garrett engineers to apply control code to the ECM, allowing customers to independently calibrate boost strategies.

Energy management is one of the key building blocks developed by Garrett on the road of technology innovation to promote predictive energy management, powertrain optimization, and vehicle health management. Garrett has extensive, proven, world-class expertise in handling multivariable control, addressing the complexities of introducing electrical energy into the vehicle and creating a more complex system with multiple objectives.